We Supply and Fit Granite Worktops in Newbury, Berkshire

Granite worktops are a timeless and elegant alternative to manufactured work surfaces, offering rich and intricate designs forged by nature over millions of years. Because of the immense heat and pressure involved in its’ formation, Granite is one of the hardest materials on Earth, making it an extremely hard wearing and scratch resistant option.

Granite work surfaces are a very popular choice and bring timeless beauty into every kitchen. Granite is one of the hardest materials on earth, formed millions of years ago beneath the earth’s surface. Worktops made from granite are extremely hard wearing & won’t scratch under normal use and are easy to clean & maintain, making them ideal worktops for kitchens & bathrooms.

Features of Granite

- Timeless beauty

- Formed millions of years ago beneath the earths surface

- One of the hardest substances on earth

- Easy to clean and maintain

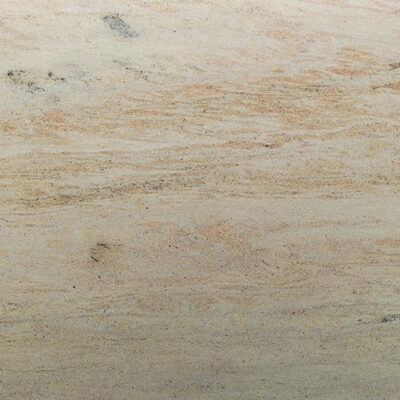

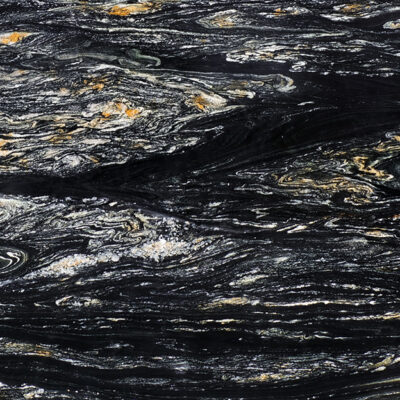

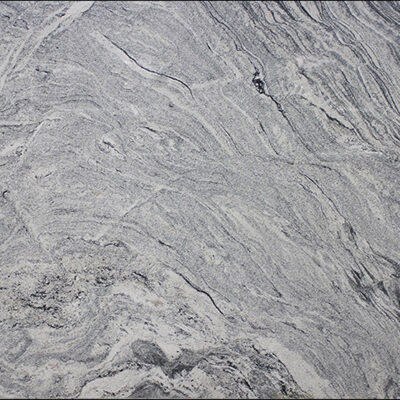

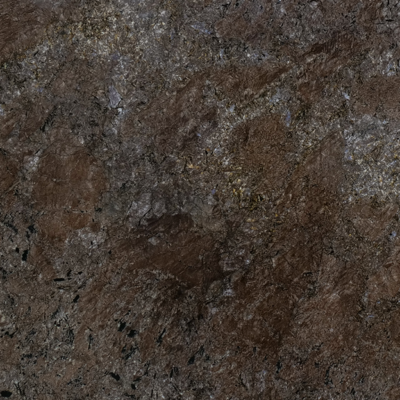

- 24 standard colours now available

- Ideal for kitchen and bathroom worktops

- Extremely hard wearing worktops, won’t scratch under normal use

Natural Veining & Pitting.

As Granite is a natural stone, pitting and veining will occur in random distribution of swirls. Subtle variations in shade or areas of contrast will also appear within the body of the worksurface. Each piece of Granite is completely unique, with it’s own unique veining patterns and frequencies. While our image samples will show veining characteristic of the particular style of Granite, please note that the final piece supplied will not be an exact replica, but will instead have its own unique aesthetic, which may differ from the exact colours or patterns displayed on this website.

Fissures, Blemishes and Natural Flaws

Some level of what could be referred to as spots or blotches are inherent in the material. Small fissures are a common feature in any Granite and these natural flaws were present at the rock formation.

Colour Variation (Drainers)

Drainer grooves and recessed drainers may be duller than the rest of the polished surface. Colour matching is not always possible as granite can vary dramatically throughout each scant. Samples provided should be used as a guide only. We will not accept any colour match issues from material that has come from the same scant.

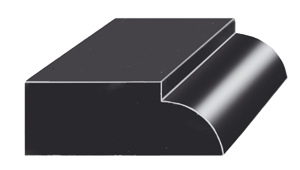

Rustic Finish

Producing the rustic finish creates minute fissures in the stone, which increase the liquid absorption & its retention of dirt & pollutants. This increase in the materials porosity will allow substances such as cooking oil & grease to penetrate on contact resulting in a stain that would be clearly evident. Please ensure that potential customers are aware that these finishes require high maintenance in the form of sealing & cleaning & a signed disclaimer is required before an order can be accepted.

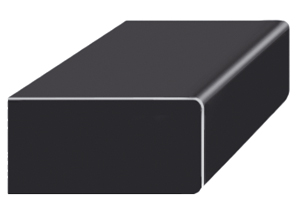

Honed Finish

A process of flattening the surface of the granite, to give a worktop with a flat low sheen & a granite work surface without reflection. Granite worktops will have a matte like appearance.

Flamed & Brushed Finish

Extreme heat is applied to the granite work surface to create a deeply textured surface. This granite work surface is then also brushed with a coarse wire rotary brush resulting in some of the roughness being removed – a textured, lightly rippled & smooth finish to the granite worktop is achieved.

Leather Finish also available on some products, please contact our Sales office for further information

A worktop finish resulting from treating the stone surface with a coarse wire rotary brush, creating a worktop with a smooth but undulated, leather like finish.

For more information, visit our Natural Products subsection.

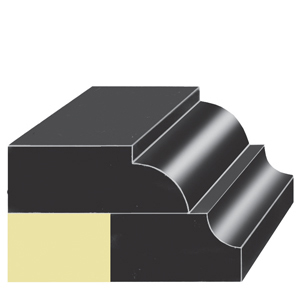

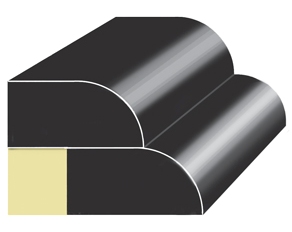

Quartz worktops come with a double bevel finish as standard, though this is only one of a range of finishes that can be completed by our team of specialised technicians, some of which can be completely transformative to the final appearance of your worktop.

While Double Bevel Edge is included in the linear metre price of a worktop, please note that all other edges will carry an additional charge.

Imperial, Full Bullnose, Single Ovolo, Milano & Venetian require a scribed joint.

Birds Beak, Milano and Venetian edges are only available in 20/20mm.

Please contact our sales team to ask about our exclusive “Deeper Downturn” manufacturing capabilities, offering from 60-100mm downturns in a limited range of colours.

Internal profile edges on double and single radius edge details other than bevelled edges must have a radius of at least 60mm. Bevel edges don’t have this constraint as they are hand finished.

The normal joint for these materials will be a standard Butt Joint ending with a 5mm overhang, with additional options of Flush Fitting Butt joints, or a Flush Fitting Mitred Joint.

Upstands refer to an engineered ‘back wall’ of a worktop, cut from the same style of worktop, and the same batch where possible. For Granite, upstands will very rarely be cut from the same slab, and as such will not match the exact veining of the worktop for a smooth transition, though we do take every effort to match styles where possible.

Granite upstands are straight and rigid, meaning gaps will be visible where there are variations in the wall platform. Plastering or tiling should ideally be completed after the worksurface installation. We recommend that Granite upstands be installed to 100mm high, as smaller segments will typically be extremely fragile.

From our manufacturing facilities, we are able to produce worktop cutouts to high standards with minimal lead times. Our team of specialist machining and hand-tooling technicians work around the clock to consistently turnaround high-quality finished granite products.

When deciding on the layout of your cutouts, please bear the following in mind:-

- A minimum of 120mm is required between two hob cutouts

- A minimum of 50mm from the cutout to the front edge is required

- A minimum of 70mm is required between sink cutouts.

Granite surfaces can be delivered in either a polished or unpolished finish.

Drainer grooves can be machined into the surface during fabrication, creating a finishing touch for undermounted sinks.

- Helps prevent vacuum pressure beneath crockery left to dry

- May help in directing drainage, as opposed to a flat surface

- Aesthetic appearance

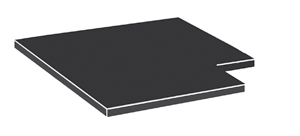

Drainer grooves as pictured can be either flat (3mm channels) or graduated (1-5mm), and are typically machined towards the small bowl in a worksurface installation, with either five or four channels.

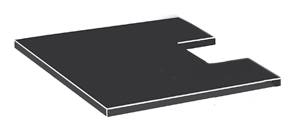

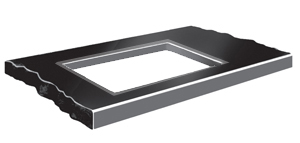

Recessed Drainers provide a flat, 3mm ingressed worktop section, which is lower than the standard surface. This localises drips and spills into a dedicated area, making it easy to direct any overspill neatly into the basin.

Please note, that both drainer grooves and recessed drainers will have a comparatively duller finish than the finished worksurface, due to the machining processes involved.

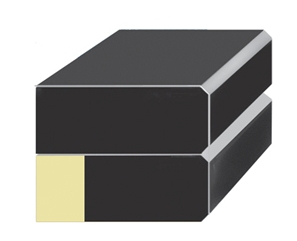

Butt Corner Joint

Typically, a quartz worktop will be joined together with a Butt-Corner Joint for simplicity, material economy, and cost savings. To avoid sharp edges, this joint has a v-groove indentation on the surface.

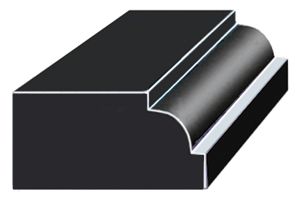

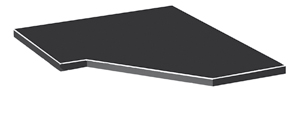

Scribed Corner Joint

For more advanced edge details, such as Imperial, Bullnose, Ovolo, Milano & Venetian, a Scribed Corner Joint will be necessary. This ensures that the edge detail can be continued around the corner, as the inside corner produced allows both worktop segments to meet along the same 45 degree vertex.

When we at Vogue supply a worktop, we include with every order our Care & Maintenance kit which includes everything you need to keep your worktop in first class condition. Follow the instructions within for a trouble free, great looking worktop.

Our detailed care & maintenance brochure can be downloaded online by clicking here

Introduction

Formed millions of years ago, granite is one of the hardest substances on earth, rating 7 on Mohs hardness scale.

Joints

Granite joints are finished with a small ariss to the top edge. Silicone sealant is applied to prevent water ingression.

Tolerance

Tolerance in granite is ±2mm

Thermal expansion

Due to thermal expansion granite can expand up to 1mm per metre. A gap of at least 3mm should be left at each end of the worktop when fitted and filled with decorators caulk. When granite is joined to other materials (such as glass, steel or wood) an elastic type of adhesive, for example polyurethane, is required for expansion.

Overhangs and supports

Any overhang extending more than 300mm must be supported.

Hob and Sink cutouts

Granite sink / hob cut outs are barred front & back (fitting of steel support bars to give additional support to cutouts), Without steel supports bars, the length of a cut out is reduced considerably. Large cut outs need to be scored and cored on occasions. This leaves the corners of the cutout in place, ready for removal on-site by the installer. Granite is susceptible to ‘blowing out’.

This occurs when contact is made with the material whilst cutting or grinding. This is very common in large particled granite. ie. we fill and seal the affected areas with epoxy resin (colour may vary) to ensure the material is not left with any sharp edges or ‘chips’.

Slips (kit form) around sink and hob cutouts are fitted in certain circumstances, if tops are too long and depending upon type and size of cutout etc.

- A minimum of 120mm is required between two hob cutout.

- A minimum of 100mm is required between hob and sink cutouts.

- A minimum of 70mm is required between two sink cutouts.

- Sink cutouts are placed a minimum 50mm from the worktop front edge.

Internal radius

Internal profile edges on all edge detail other than bevel edge must have a radius of at least 60mm. Bevel edges don’t have this constraint as they are hand finished.

Upstands

Upstands should ideally be 100mm high, as material less than this height is extremely fragile. Upstands are not normally cut from the same slab as the worksurfaces, therefore an exact colour match is not possible. Granite upstands are straight and rigid, gaps will be visible where there are variations in the wall profile. Plastering or tiling should ideally be completed after the worksurface installation.

Scratches

Granite is highly scratch resistant but not scratch proof. Small scratches of less than 25mm in length are considered ‘within tolerance’ and are considered acceptable.

Staining

Although Granite is one of the least absorbent stone’s, it can still be stained by grease, wine, coffee, nicotine, fruit juices and other strongly coloured substances. Granite worksurfaces are sealed upon installation and must be resealed every 6 months. Any spillages must be removed immediately as delay could result in permanent damage.

Stainless Steel Sinks

Please specify the preferred undermounting of Stainless Steel Sinks. Silicone sealant may be rendered ineffective when plumbing the sink in, it is important that the sink is re-sealed by the plumber, or the 12 months guarantee will be invalid if the work is not carried out. If a waste disposal unit is fitted to an undermounted sink after installation, additional support will be required, otherwise your warranty may be invalidated.

Handling

For installations you will need to supply additional labour on orders, which have worktops weighing above 150kg. Every additional 75kg requires an extra person to assist with lifting. Size of ‘scant’ or ‘slab’, is a major factor in selecting the maximum usable length of a work surface. Approximately 2.8m x 1.3m is the largest work surface we are able to manufacture, this may be drastically reduced if you require a cutout, especially in granite with larger crystals. Due to the weight of granite, please ensure that your units are level and securely fixed.