Silestone Kitchen Worktops

Design, Durability and Hygiene

High resistance to stains and knocks. Endless colour possibilities to suit all kitchen styles.

Kitchens to live in

We have reached millions of homes in over 100 countries, creating experiences that improve peoples lives.

Inspiring Bathrooms

Unique and personalized spaces, with colors and textures in perfect balance where quality prevails.

Sustainable Innovation

Sustainability and innovation come together in surfaces composed of minerals and recycled materials.

Silestone Worktops

Information

Quartz has been a leading choice for worktops for many years, favoured for the complex range of styles and finishes available, and it’s hard-wearing durability.

Features of Quartz

- Wide selection of attractive and modern styles to choose from

- Strong & Durable work surface

- Scratch resistant worktops

- Easy to clean & maintain

- Non-porous & hygienic

- Stain & heat resistant

- Crystalline quartz appearance

- Uniform in colour and thickness

About the Silestone Eco Range

ECO by Cosentino¨ is an original product manufactured from 75% of recycled materials such as mirror, glass, porcelain, earthenware, and vitrified ash. Even 94% of the water used in its manufacturing process is re-used. ECO by Cosentino¨ is a product that embraces sustainability, design and quality that has produced a new category of recycled surfaces. These are an ecological alternative to similar surfaces available for construction and decoration.

Colour Variation

Silestone is manufactured on a continual processing line. Each mixed batch only produces around 150 – 200 slabs so colour can vary slightly between batches.

Since Silestone is manufactured from natural quartz, variations in the colour, shape and pattern of the stone may occur and unique characteristics are to be expected with this product. Such variation does not affect the products performance in any manner. Samples are only a representative and are not an exact replication of what will be installed.

In addition, variations in shade, the density of coloured features and veining or areas of contrast are all common within veined Quartz, occasionally this can be quite dramatic in both veining and colour groups, within each worktop and between worktops in a kitchen.

Surface Appearance

In some cases, areas of ‘milkiness’ and swirls can be evident. This could arise from natural variation in the colour of the quartz stone itself, a pigment drip or foreign material.

Plain colours are easier to manufacture but harder to keep uncontaminated during manufacture e.g. light colours may have small dark spots, darker colours may appear patchy with lighter spots.

Pinprick ‘pitting’ of the surface is a common feature of engineered (quartz) stone and arises from the release of air/gas during the manufacturing process.

All above are inherent in the manufacturing process of engineered stone and are not considered defective.

| Style | Polished Band | Suede Band | Notes | Style | Polished Band | Suede Band | Notes |

| Blanco City | 1 | 1 | Blanco Zeus Extreme | 4 | N/A | ||

| Gris Expo | 1 | 1 | Iconic Black | 4 | N/A | ||

| Marengo | 1 | 1 | Haiku | 4 | 4 | ||

| Noka | 1 | 1 | Kensho | 4 | 3 | ||

| Rougui | 1 | 1 | Snowy Ibiza | 4 | 3 | Random Veining | |

| Arden Blue | 2 | 1 | Unsui | 4 | 3 | ||

| Blanco Norte | 2 | 1 | Ariel | 5 | 4 | Random Veining | |

| Cemento Spa | 2 | N/A | White Arabesque | 4 | 4 | Random Veining | |

| Coral Clay | 2 | 1 | Random Veining | Blanco Orion | 5 | 4 | Random Veining |

| Iron Bark | 2 | 1 | Random Veining | Calypso | 5 | 4 | Random Veining |

| Negro Tebas | 2 | 1 | Charcoal Soapstone | 5 | 4 | Random Veining | |

| Niebla | 2 | 1 | Daria | 5 | 4 | Random Veining | |

| Royal Reef | 2 | 1 | Eternal Emperador | 5 | N/A | Random Veining | |

| Altair | 3 | 3 | Random Veining | Eternal Marquina | 5 | 4 | Random Veining |

| Aluminio Nube | 3 | N/A | Eternal Marfil | 5 | 5 | Random Veining | |

| Blanco Capri | 3 | 2 | Eternal Serena | 5 | 4 | Random Veining | |

| Blanco Maple | 3 | 2 | Helix | 5 | 5 | Random Veining | |

| Desert Silver | 3 | 3 | Random Veining | Iconic White | 5 | 4 | |

| Kenosho | 3 | N/A | Random Veining | Lagoon | 5 | 4 | Random Veining |

| Negro Anubis | 3 | 3 | Luna | 5 | N/A | ||

| White Storm | 3 | 2 | Lyra | 5 | 4 | Random Veining | |

| Alpine White | 3.5 | N/A | Merope | 5 | 4 | Random Veining | |

| Amazon | 3.5 | 3 | Pearl Jasmine | 5 | 5 | Random Veining | |

| Blanco River | 3.5 | 3 | Random Veining | Pulsar | 5 | N/A | Random Veining |

| Classic White | 3.5 | 3 | Vortium | 5 | 4 | Random Veining | |

| Crema Stellar | 3.5 | N/A | Bianco Calacatta | 6 | 5 | Random Veining | |

| Grey Stellar | 3.5 | N/A | Carbono | 6 | 5 | ||

| Lusso | 3.5 | N/A | Random Veining | Chrome | 6 | 5 | |

| Negro Stellar | 3.5 | N/A | Classic Calacatta | 6 | 5 | Random Veining | |

| Tigris Sand | 3.5 | 3 | Random Veining | Eternal Calacatta Gold | 6 | 5 | Random Veining |

| Yukon | 3.5 | 3 | Eternal Staturio | 6 | N/A | Random Veining | |

| Blanco Zeus | 4 | 3 | Random Veining | Iron Ore | 6 | N/A | |

| Bamboo | 4 | N/A | White Platinum | 6 | N/A | ||

| Eco Styles | Polished Band | Suede Band | Notes | Eco Styles | Polished Band | Suede Band | Notes |

| Crystal Ash | N/A | 3 | Luna | 6 | N/A | ||

| Polar Cap | 6 | 3 | Iron Ore | 6 | 5 | ||

| Crystal Sand | N/A | 4 | Riverbed | 6 | N/A | ||

| Forest Snow | 6 | N/A | Terra | 6 | N/A | ||

| Starlight | 6 | N/A | White Diamond | 6 | N/A | ||

| Creamstone | 6 | N/A | Random Veining | Red Pine | 6 | N/A | |

| Grey Moss | 6 | N/A |

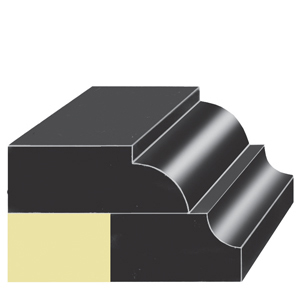

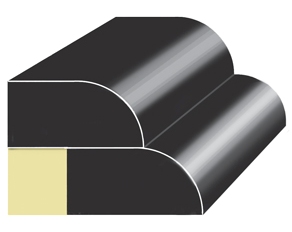

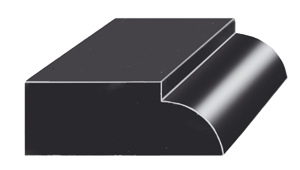

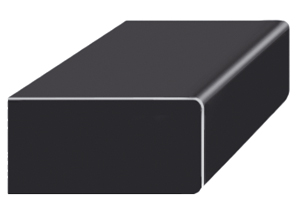

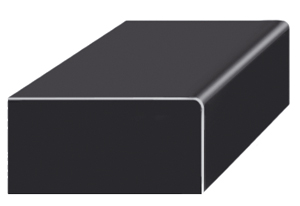

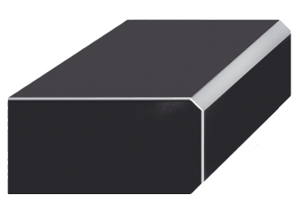

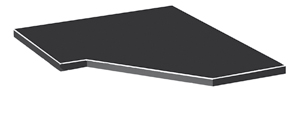

Sheridan Apollo Quartz worktops come with a double bevel finish as standard, though this is only one of a range of finishes that can be completed by our team of specialised technicians, some of which can be completely transformative to the final appearance of your worktop.

While Double Bevel Edge is included in the linear metre price of a worktop, please note that all other edges will carry an additional charge.

Imperial, Full Bullnose, Single Ovolo, Milano & Venetian require a scribed joint.

Birds Beak, Milano and Venetian edges are only available in 20/20mm.

Please contact our sales team to ask about our exclusive “Deeper Downturn” manufacturing capabilities, offering from 60-100mm downturns in a limited range of colours.

Internal profile edges on double and single radius edge details other than bevelled edges must have a radius of at least 60mm. Bevel edges don’t have this constraint as they are hand finished.

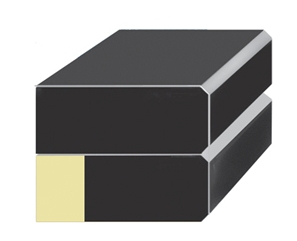

The normal joint for these materials will be a standard Butt Joint ending with a 5mm overhang, with additional options of Flush Fitting Butt joints, or a Flush Fitting Mitred Joint.

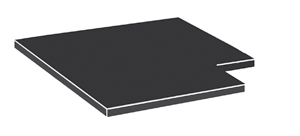

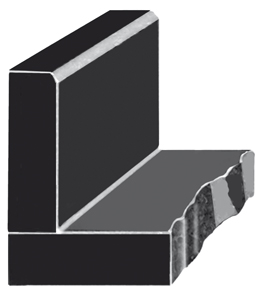

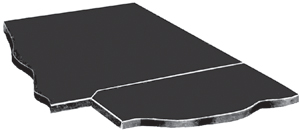

Upstands refer to an engineered ‘back wall’ of a worktop, cut from the same style of worktop, and the same batch where possible. Products with strong patterns will not have direct continuation onto this upstand section, though we will endeavor to provide worktops with as close a match as can be achieved economically.

As standard, we offer upstands in 100mm, and 60mm (as below, respectively).

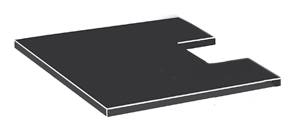

From our manufacturing facilities, we are able to produce worktop cutouts to high standards with minimal lead times. Our team of specialist machining and hand-tooling technicians work around the clock to produce hundreds of tailored quartz worktops every month.

When deciding on the layout of your cutouts, please bear the following in mind:-

- A minimum of 120mm is required between two hob cutouts

- A minimum of 50mm from the cutout to the front edge is required

- A minimum of 70mm is required between sink cutouts.

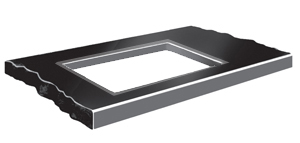

Drainer grooves can be machined into the surface during fabrication, creating a finishing touch for undermounted sinks.

- Helps prevent vacuum pressure beneath crockery left to dry

- May help in directing drainage, as opposed to a flat surface

- Aesthetic appearance

Drainer grooves as pictured can be either flat (3mm channels) or graduated (1-5mm), and are typically machined towards the small bowl in a worksurface installation, with either five or four channels.

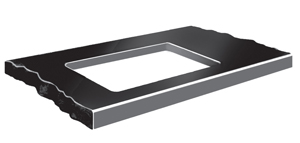

Recessed Drainers provide a flat, 3mm ingressed worktop section, which is lower than the standard surface. This localises drips and spills into a dedicated area, making it easy to direct any overspill neatly into the basin.

Please note, that both drainer grooves and recessed drainers will have a comparatively duller finish than the finished worksurface, due to the machining processes involved.

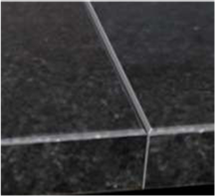

Butt Corner Joint

Typically, a quartz worktop will be joined together with a Butt-Corner Joint for simplicity, material economy, and cost savings. To avoid sharp edges, this joint has a v-groove indentation on the surface.

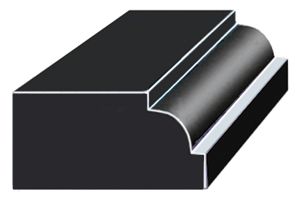

Scribed Corner Joint

For more advanced edge details, such as Imperial, Bullnose, Ovolo, Milano & Venetian, a Scribed Corner Joint will be necessary. This ensures that the edge detail can be continued around the corner, as the inside corner produced allows both worktop segments to meet along the same 45 degree vertex. Quartz joints/notches are finished with a small arris to the top edge to remove sharp edges. Sealant is applied between the two pieces to prevent water ingression, it’s not used to fill the joint. The joint when completed will show a small V-Groove, as illustrated below.

When we at Sheridan supply a worktop, we include with every order our Care & Maintenance kit which includes everything you need to keep your worktop in first class condition. Follow the instructions within for a trouble free, great looking worktop.

Introduction

Silestone® is made from an amazing 93% quartz with the remaining 7% polymer binder.

- Complete with polished finish.

- Ideal for vanity tops, worksurfaces, cladding etc.

- Extremely hard, 7 on the ‘Moh’s Hardness scale’.

- The quartz used coupled with highperformance, stain resistant polymers results in a durable, non-porous, chemical resistant surface.

- Silestone® keeps its lustrous gloss and ultra-smooth surface without polishing. Because it is non-porous, it does not require sealants or waxes.

Tolerance

Tolerance in Silestone® is ±2mm

Joints

Silestone® joints are finished with a small ariss to the top edge, silicone sealant is applied to prevent water ingression.

Thermal expansion

Due to thermal expansion Silestone® can expand up to 1mm per metre. A gap of at least 3mm should be left at each end of the worktop when fitted and filled with decorators caulk. When Silestone® is joined to other materials (such as glass, steel or wood) an elastic type of adhesive, for example polyurethane is required for expansion.

Overhangs and supports

Any overhang extending more than 300mm must be supported.

Hob & Sink cutouts

- A minimum of 120mm is required between two hob cutout.

- A minimum of 100mm is required between hob and sink cutouts.

- A minimum of 50mm is required between two sink cutouts.

- Sink cutouts are placed a minimum of 50mm from the worktop front edge.

Internal radius

Internal profile edges on all edge detail other than bevel edge must have a radius of at least 60mm. Bevel edges don’t have this constraint as they are hand finished.

Upstands

Upstands should ideally be 100mm high, as material less than this height is extremely fragile. Upstands are not normally cut from the same slab as the worksurfaces, therefore an exact colour match is not possible. Silestone® upstands are straight and rigid, gaps will be visible where there are variations in the wall profile.

Plastering or tiling should ideally be completed after the worksurface installation.

Scratches

Silestone® is scratch resistant but not scratch proof. Small scratches less than 25mm in length are considered within tolerance by the manufacturer and are considered acceptable.

Stainless Steel Sinks

Please specify the preferred undermounting of Stainless Steel Sinks. Silicone sealant may be rendered ineffective when plumbing the sink in, it is important that the sink is re-sealed by the plumber, or the 12 months guarantee will be invalid if the work is not carried out.

If a waste disposal unit is fitted to an undermounted sink after installation, additional support will be required, otherwise your warranty may be invalidated.

Handling

For installations you will need to supply additional labour on orders which have worktops weighing above 150kg. Every additional 75kg requires an extra person to assist with lifting. Size of ‘scant’ or ‘slab’, is a major factor in selecting the maximum usable length of a work surface. Approximately 3m x 1.3m is the largest work surface we are able to manufacture, this may be drastically reduced if you require a cutout.

Due to the weight of Silestone®, please ensure that your units are level and securely fixed.